Solutions

For Solid Edge Users

Solutions for Solid Edge

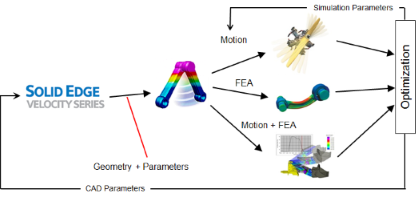

SimWise 4D is the most cost-effective simulation product that is integrated with Solid Edge. It can bi-Directionally transfer parts, assemblies, assembly relations, design variables and dimensions from Solid Edge to SimWise. Once within SimWise simulation specific information can be added resulting in a functional operating prototype allowing a multitude of Simulations to be run directly using the information from Solid Edge.

If the Solid Edge model is modified, the changes can be sent from Solid Edge to SimWise, where the modification will be reflected in the SimWise model without effecting any Simulation specific information added to the SimWise model.

SimWise provides the following simulation capabilities:

- 3D Dynamic Motion simulation including the ability to model 3D contact, gears, actuators and connections between parts. Solid Edge relations are automatically converted to motion joints.

- Finite Element Analysis (FEA) including static, normal modes, buckling, steady state and transient thermal, and combined structural thermal analyses.

- Combined Motion and FEA simulation allowing the dynamic forces resulting from the motion of your design to be combined with other loading conditions to produce a complete stress profile of your design as it moves throughout its range of motion

- Optimization allows Solid Edge dimensions and variables along with simulation specific quantities to be used as optimization parameters and constraints. Multiple motion, FEA, or Motion + FEA simulations are run to allow a design objective like minimum weight or maximum speed to be achieved.

- Co-Simulation with MatLab/Simulink allows a SimWise model to be used as a Simulink plant model providing for a control system modelled in SimuLink to control a SimWise motion model. The control system can be validated against a mechanical model that incorporates all of the physical effects or the real thing.

- Fatigue Life Calculations can be determined using the optional SimWise Durability module. The stress time history calculated by a Motion + FEA simulation is used to determine the fatigue life of any part in the assembly.

SimWise 4D provides the following:

| Feature | Benefit |

|---|---|

| Desktop product integrated within Solid Edge. | Product is built and streamlined for Simulation. No need to use a Solid Edge license while simulating. |

| Extensive set of simulation capabilities. | Handle your current simulation needs and ready for your future needs. 3D Dynamic Motion, FEA, Optimization, Control System Co-simulation, and Fatigue life calculations. |

| Bi-directional data flow. | Solid Edge variables and dimension can be used with optimization allowing part shape to be modified by SimWise optimization engine. Geometry updates reflected in simulation model while maintaining simulation specific objects. |

| Virtual prototype of your design. | Allows questions like "Does it Work?", "Will it Break?", "How long will it last?" and "Where can it be improved?" to be answered without building physical hardware or running physical tests. |

| Cost effective. | Provides high-end simulation capabilities at a cost compatible with your Solid Edge licenses. |

| View Videos | Download a Brochure | Request a Quote | Request an Evaluation |